:

[email protected]

:+86-13356197682

In today's manufacturing industry, injection molding is a common plastic processing method widely used in various industries. Especially in the new energy industry, the application of plastic supports and covers in new energy stacks is becoming increasingly widespread. in order to meet the needs of various complex shapes and specifications ,customized injection molds have become a necessary solution.

Injection molding is a thermoplastic molding method, whose basic principle is to heat the plastic raw material to a molten state, then inject the molten plastic into the mold through a syringe, cool it, and then open the mold to take out the molded product. Injection molding has the advantages of high production efficiency, strong customizability, and low cost, making it widely used in fields such as automobiles, electronics, healthcare, and new energy.

In new energy stacks, plastic brackets and covers are mainly used to protect battery cells and connecting components to ensure the normal operation and safety of the stack. These components need to meet a series of specific requirements such as high temperature resistance, corrosion resistance, insulation performance, strength, etc. Through the injection molding process, plastic components that meet these strict requirements can be efficiently and accurately manufactured.

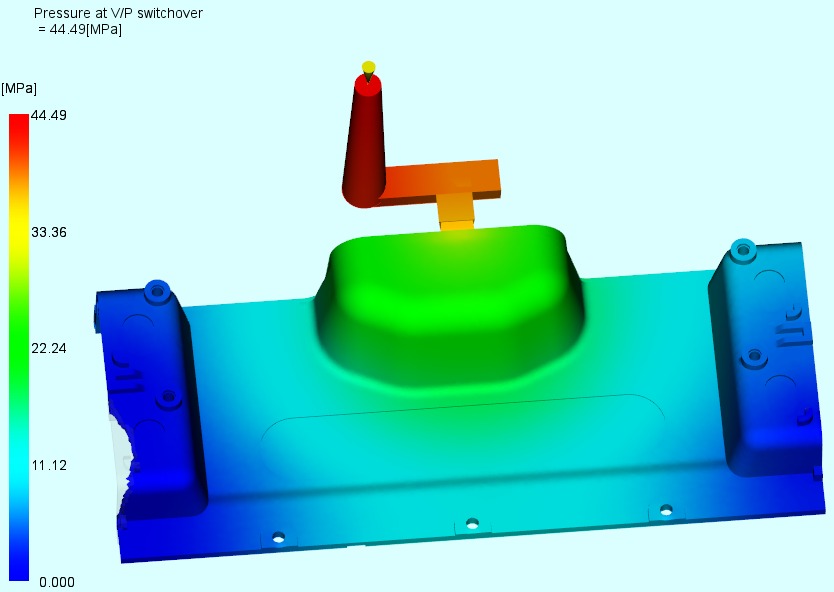

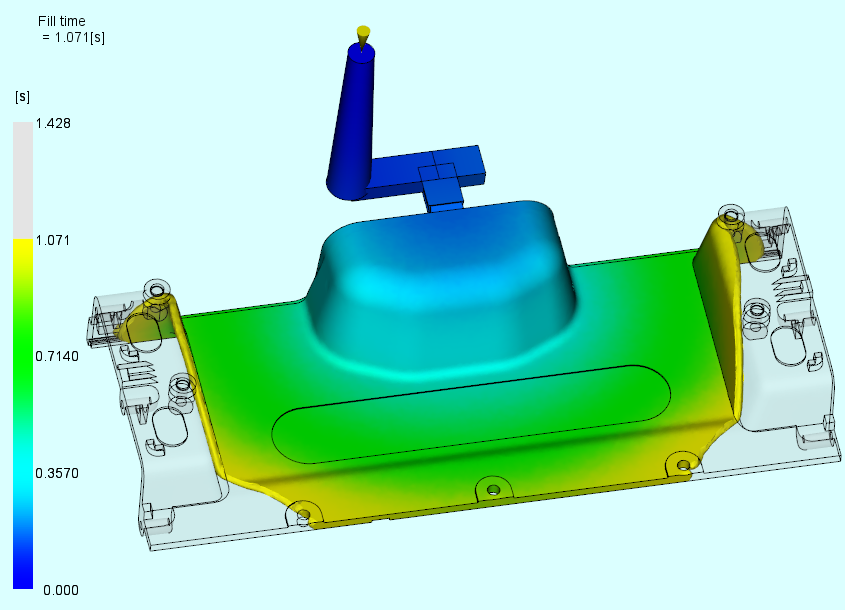

Injection molds are the core part of the injection molding process, and their design directly affects the quality and production efficiency of products. In the field of new energy stacks, injection molds need to be customized according to the structure and size of the stack to ensure the accuracy and consistency of the products. During the mold design process, multiple factors need to be considered, such as material selection, flow analysis, cooling system design, etc.

With the continuous progress of new energy technology, the application prospects of new energy stacks are becoming increasingly broad. In the future, new energy stacks will be more efficient, reliable, and safe, and the requirements for plastic supports and covers will also be higher. The injection molding process will play an important role in the development of new energy stacks, providing strong support for promoting the development of the new energy industry.

In a word , by optimizing injection mold design and production process, the performance and quality of plastic supports and covers can be further improved to meet the strict requirements of new energy stacks. In this process, customized injection molds will become an important solution, providing strong support for promoting the development of the new energy industry.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at [email protected] or use the following enquiry form. Please allow us to provide you with the best service.