Rapid Prototyping & Manufacturing, It is a new advanced manufacturing technology rising and developing rapidly in recent years , Its feature is that it can quickly manufacture extremely complex parts without machining equipment or molds, thus saving time and initial investment in small batch production or trial production of new products.

RPM technology is mainly applied to the design verification and trial production of simulation samples for the development of new products (including product upgrading), that is, to complete the development process from the conceptual design (or modification design) of products to the modeling design ----- the structural design ----the basic function evaluation ----- the trial production of simulation samples.

(1) Design verification and function verification in the process of new product development..

(2) Manufacturability and assemblability inspection.

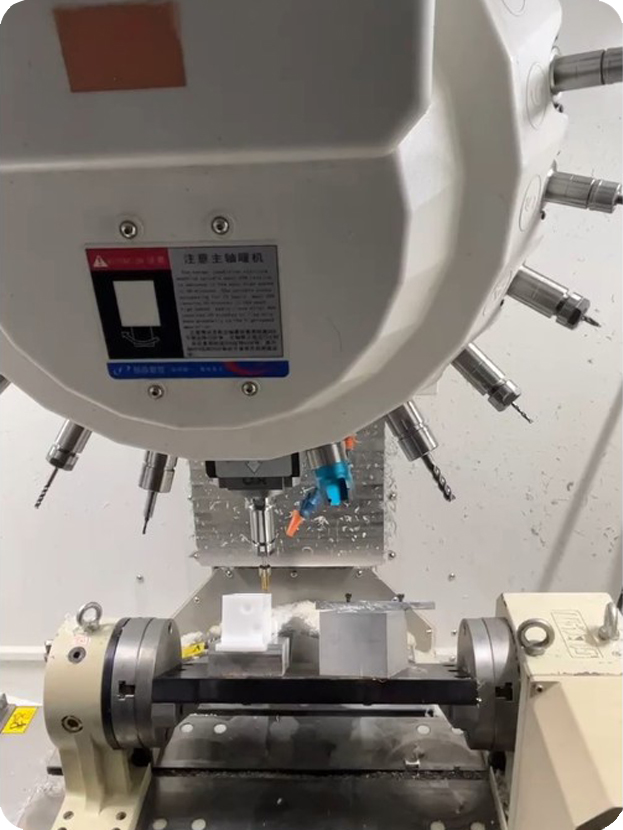

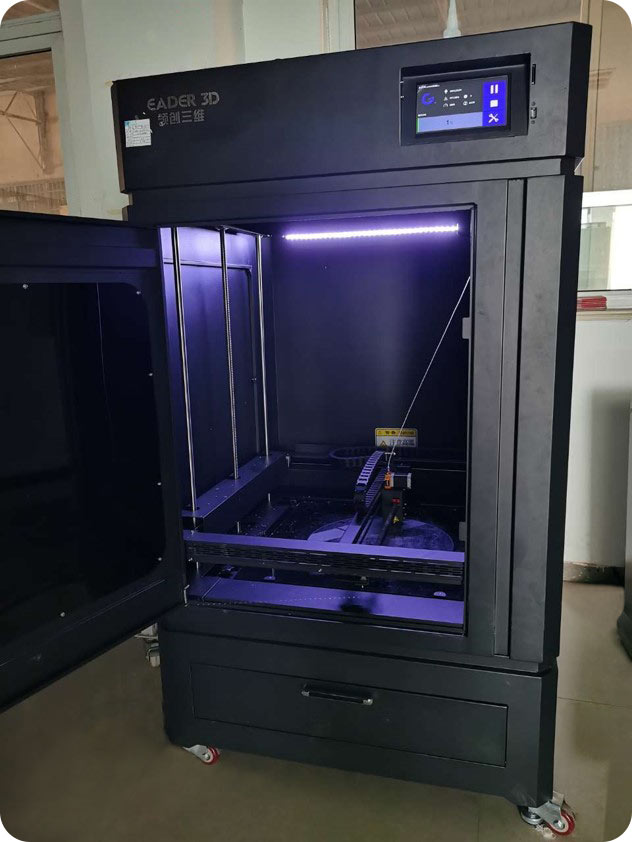

(3) Direct production of single piece, small batch and special complex parts.

When manufacturing product prototypes to support product development, 3D printing and CNC machining are two prototyping processes that need to be considered. How to choose between these two processes in specific applications, especially when the design and product specifications have not been finalized , following are showing the difference .