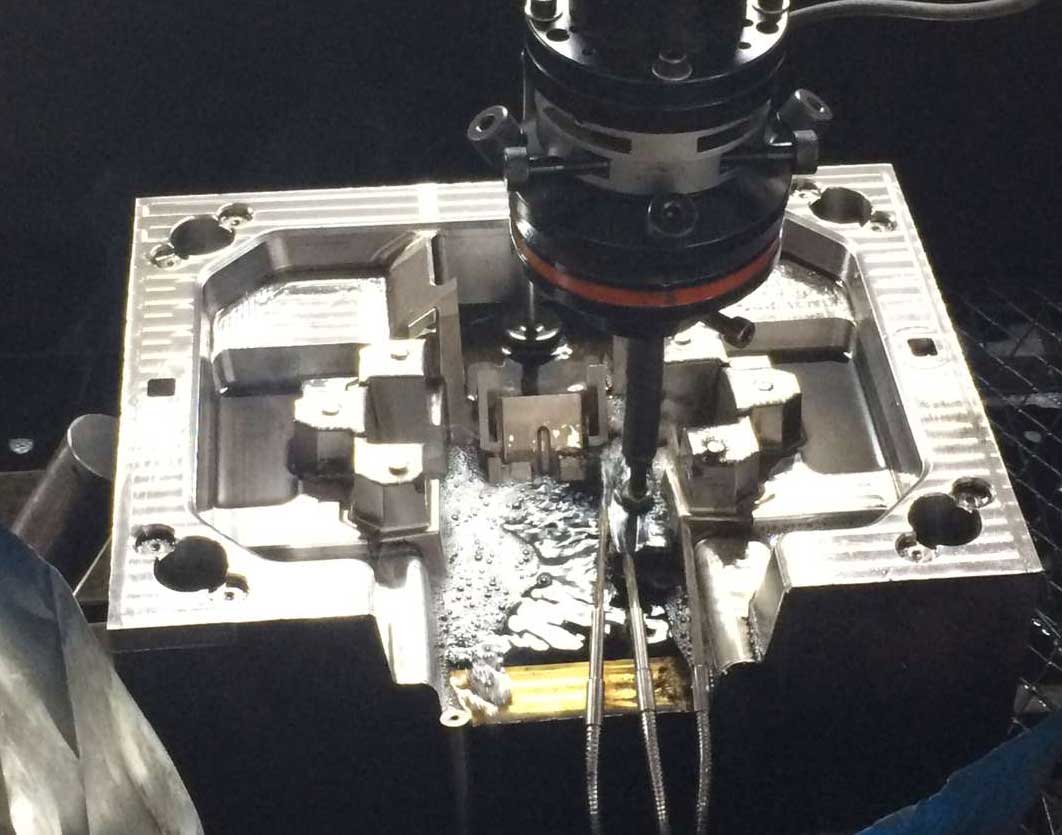

Plastic mold making

In order to ensure the processing efficiency and quality assurance of the mold department and realize modern management and control.

Bemould company introduces ERP system and MES system, so that the production department can improve the manufacturing execution and delivery ability; Grasp changes in time, on time and in real time, on demand, trace the

source of the production process as far as possible, and meet the compliance requirements;

Realize the information synchronization of each department and realize the intelligent production mode.

Why you should choose us for the plastic injection molding & mold manufacturing?

- 12 hours to reply your inquiry

- Less than two days to offer quotation

- Design For Manufacture analysis before mold manufacturing

- 2D and 3D mold drawing for your approval

- Weekly report with picture for mold making

- Inspection report and Molding parameter report for mold trial

- Heat treatment report for mold steel

- Mold base certification

- Mold steel certification

- Plastic injection molding capacity

- Support & offer shipping

- Prototype for plastic tube fitting capacity

- 7 years experience for international business

- Most of engineers have more than ten years experience

- Professional project manager work with, speak in English