Common injection defects and optimization methods

Q1: cold material mark at gate position

Describe

Product

material PC , color , clear ,hot runner with side gates .

Defects

There are

obvious surface defects such as cold material mark and water spray at the

gate on the product surface .

Cause

1. The

material flow quickly from the gate through the runner , enters the product surface. at the moment of entering the mold, the material

with high temperature cools instantly, forming cold material marks on the

surface.

2. Gate

location problems , the material flows through the gate and directly rushes

to the product surface without buffer.

Optimization

Change the side gate to sub-gate ,to avoid the material flow to rush

directly onto the product surface. it should be designed at the product

flanging to buffer the turbulent material flow.

Results

Changed the gate type, the product defects get solved

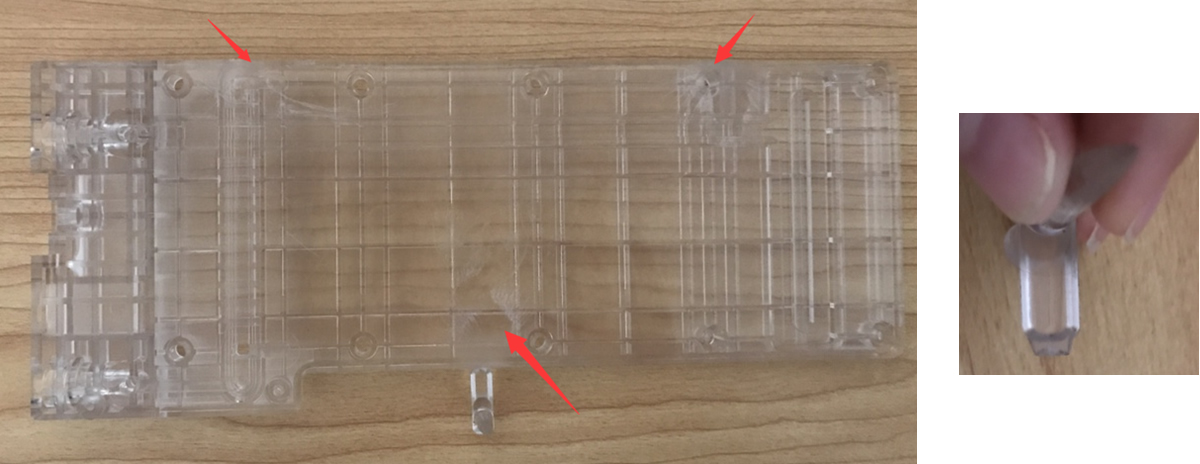

Q2 :The sizes of both sides of transparent thin-walled parts are different .

Describe

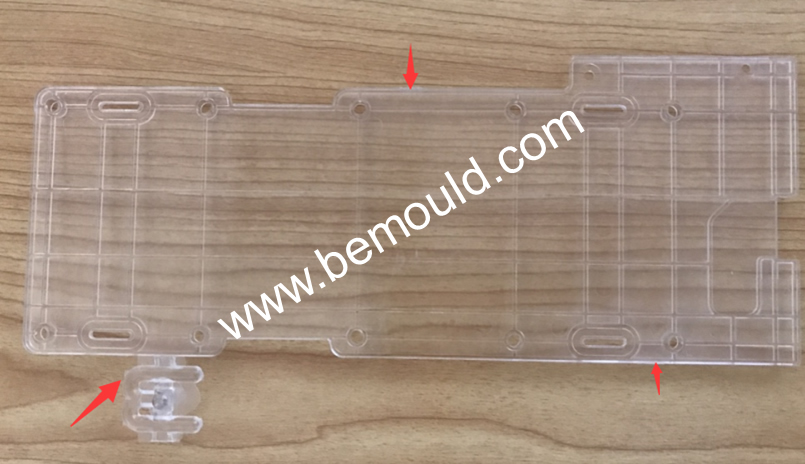

Product

material PC , color , clear ,hot runner with side gates .

There are some area

Defects

Obvious

shrinkage on one side of the product and inconsistent dimensions on both

sides.

Cause

The product

has one gate on one side and two gates on the other side. The filling of

thin-walled parts is unbalanced , if 2 gates on two sides , there will be obvious air

traps in the middle of the product, which cannot be eliminated by exhaust .

Optimization

It is recommended to increase the wall thickness of the product from

the original 1.5mm to 1.7mm

Results

The product defects get solved

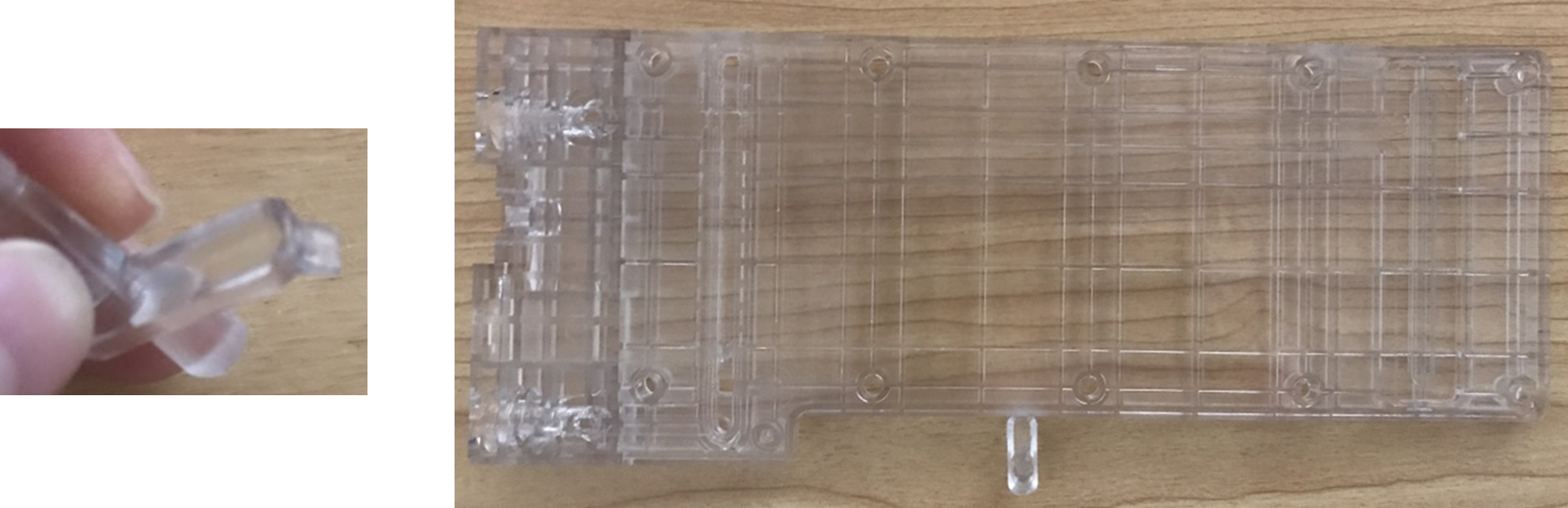

Q3: short shot at thin wall thickness position

|

Describe |

Product material PC , color , clear ,hot runner with side gates . The wall thickness of the inner frame of the product is about 0.8mm . |

|

Defects |

Short shot at thin wall thickness position(0.8mm)

|

|

Cause |

If the wall thickness of the product is too thin, the material flow shall first fill the position with thicker wall thickness, and then return to the position where the material shortage is filled. The thin wall position may be frozen, and the refilled material needs to cross the cold material to fill the empty space. The pressure required will increase and the exhaust is not enough. |

|

Optimization |

Additional exhaust for mould |

|

Results |

The product defects get solved |

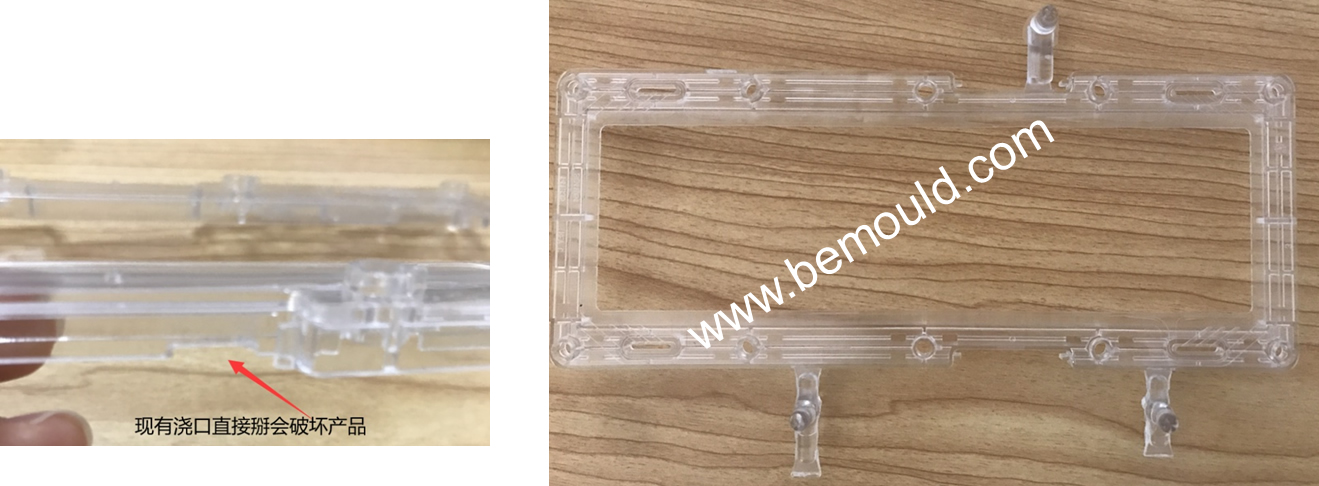

Q4: Requirements of product gate position on strength

|

Describe |

Product material PC , color , clear ,hot runner with side gates . The wall thickness of the inner frame of the product is about 0.8mm . |

|

Defects |

Cutting the gate will damage the product |

|

Cause |

The side gate is designed at the product parting position, where the strength is not enough, and the side gate is 9 * 1mm, which is easy to damage the product when cutting the gate. |

|

Optimization |

Change the gate type from side gate to sub-gate |

|

Results |

The product defects get solved |