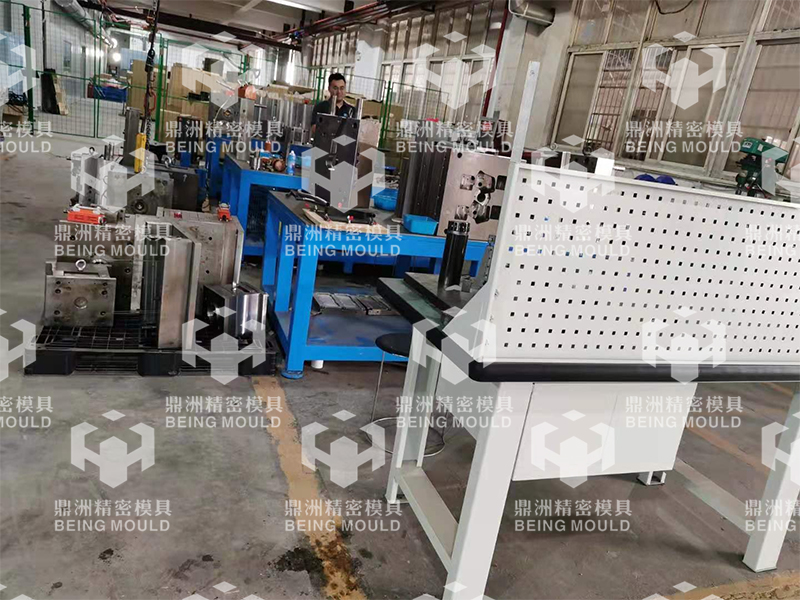

Dingzhou Injection mold workshop --EDM

Common processing procedures of injection mold, EDM, Dingzhou plastic mold will take you to understand the basic knowledge of EDM

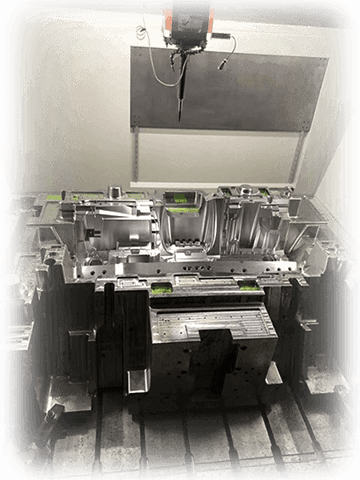

1、 What is EDM Electric spark is a self-excited discharge with the following characteristics: There is a high voltage between the two electrodes of spark discharge before discharge. When the two electrodes are close, the dielectric is broken down, and then spark discharge occurs. With the breakdown process, the resistance between the two electrodes decreases sharply, and the voltage between the two poles also decreases sharply.

2、 Characteristics of EDM , EDM is a new technology completely different from machining. With the development of industrial production and the progress of science and technology, new materials with high melting point, high hardness, high strength, high brittleness, high viscosity and high purity continue to appear. There are more and more workpieces with various complex structures and special process requirements, which makes the traditional machining methods unable or difficult to process. During machining, the tool electrode is not in contact with the workpiece material, and the macro force between them is very small. The tool electrode material does not need to be harder than the workpiece material, so the tool electrode is easy to manufacture.