How to optimize the warpage caused by fiber orientation

Product warpage is always a difficult problem in the research of injection molded parts, and the warpage of glass fiber reinforced plastic parts is even more complicated .

As an OEM manufacturer of plastic accessories for new energy batteries, we have accumulated years of experience and excellent professional knowledge to summarize the problems and solutions encountered in daily production into the company's know-how knowledge base for everyone to view and learn .

We know that plastic products will shrink. In an ideal state, uniform shrinkage is only a change in product size. However, the actual production is due to various factors (such as product structure, wall thickness, materials...) The product shrinkage is uneven due to the influence of, and the product warps due to uneven shrinkage.

Generally, the following factors affect the product shrinkage: uneven product shrinkage uneven cooling uneven orientation caused by glass fiber in the product . Today, we will focus on how to optimize the warpage caused by uneven orientation at point 3.

1.As we know the shrinkage principle of plastic parts with glass fiber filling .

2.1 Case study , part material PA66-30%GF

Conclusion : filling balance, get a uniform fill pattern will improve part warp .

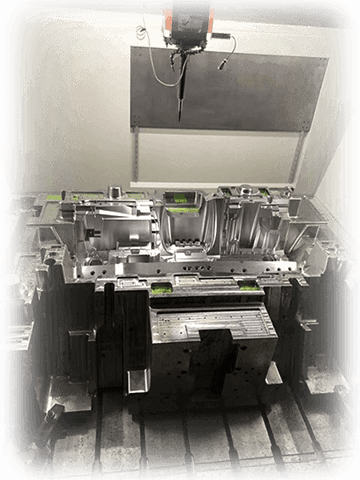

2.2 Case study , part material PBT-30%GF

It’s required a flatness of 0.1mm at part bottom, obviously , we can know that out of tolerance

from the analysis result .

It shows original design and part warpage .

I tried lots of schemes to verify part warp , filling uniform , gate location adjustment … , many

schemes have been tried and are invalid.

At the last , I update the feature design as follows .

Conclusion : The balance of product structure design can improve the shrinkage anisotropy of

glass fiber reinforced materials