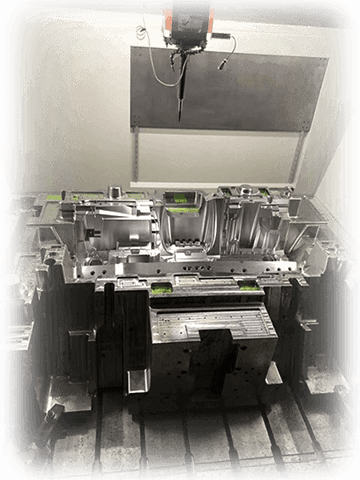

How to solve the problem of product ejection pin marks in injection shell mold factory

Injection molding shell mold factories often encounter the phenomenon of product top white in the process of injection molding production. when many injection molding manufacturers encounter this phenomenon, they have to make a temporary solution in order to catch up with the goods. the solution is to use release agent. however, the use of release agent will directly affect the appearance of the product, and even more use will break the plastic properties of the product, so as to reduce the future use efficiency of the product. Moreover, the use of release agent also increases the production cost. Therefore, the best way for the injection shell mold factory to solve the product top white phenomenon is to start with the mold top out structure.

In order to completely solve the product top white phenomenon, the injection shell mold factory must check whether the thimble can be added at the top white part, whether there is a bone position that does not save light and slip, and if there are still spark lines at the bone position, it is the most likely to cause top white. Another reason is that the die inclination of a certain part of the product is not enough. If this is the reason, it must be reprocessed to ensure that there is enough die inclination before the top white phenomenon can be cut off. Otherwise, no matter how you save light and slip or add a thimble, the top white problem can not be completely solved .