Injection molding defects : Clod flow lines

Cold flow lines, also known as sun spot and fog spot, refers to the circular color change near the gate, which is usually determined by the pouring method and gate size. The reason is melt fracture

reduce the injection speed, injection pressure, increase the mold melt temperature and mold temperature to improve the fluidity of the material.

As for mold: reasonable gate size, reduce material flow resistance and reasonable cold well design.

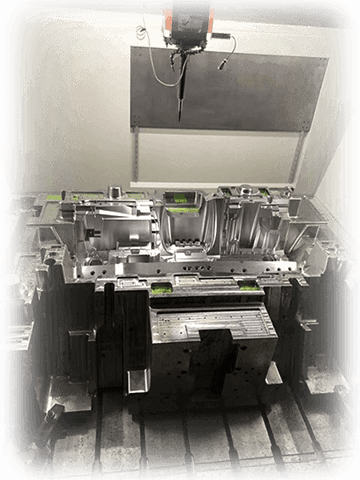

For example, the gate cold flow lines of new energy power equipment accessories, non appearance parts and products started in the morning is obvious , as the running time of the machine increases, the mold temperature and material temperature of the machine rise gradually, and the defect will be improved slowly.

Share to: