Plastic Injection Overmolding Solution

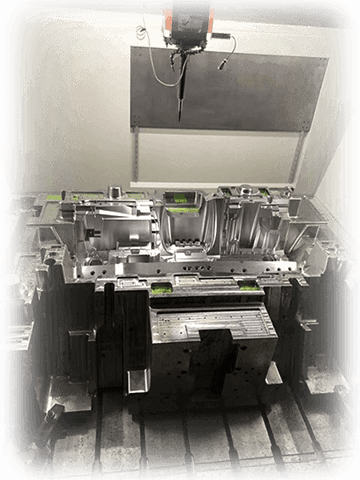

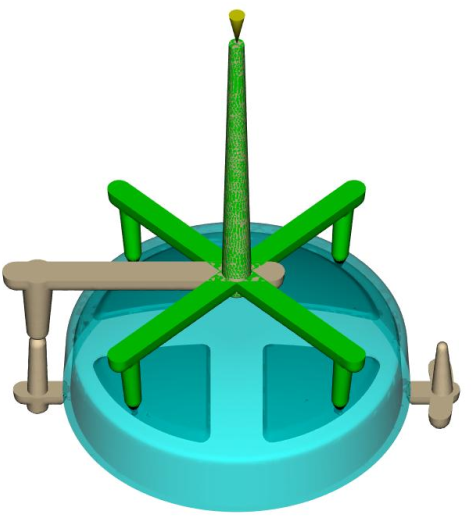

Plastic product information:

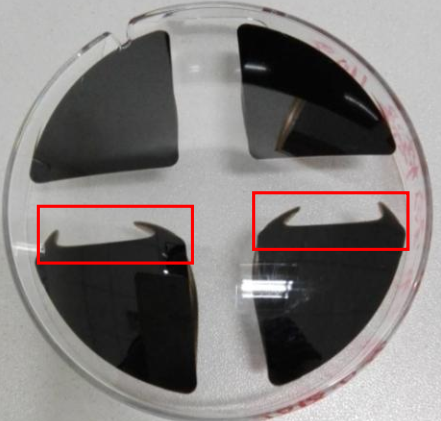

the first shot :Black PC the second shot :PC(clear) Common injection molding defects in two-shot injection molding :

|

|

|

|

|

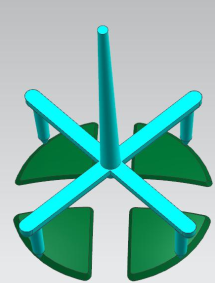

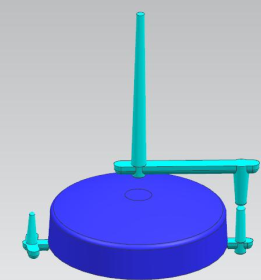

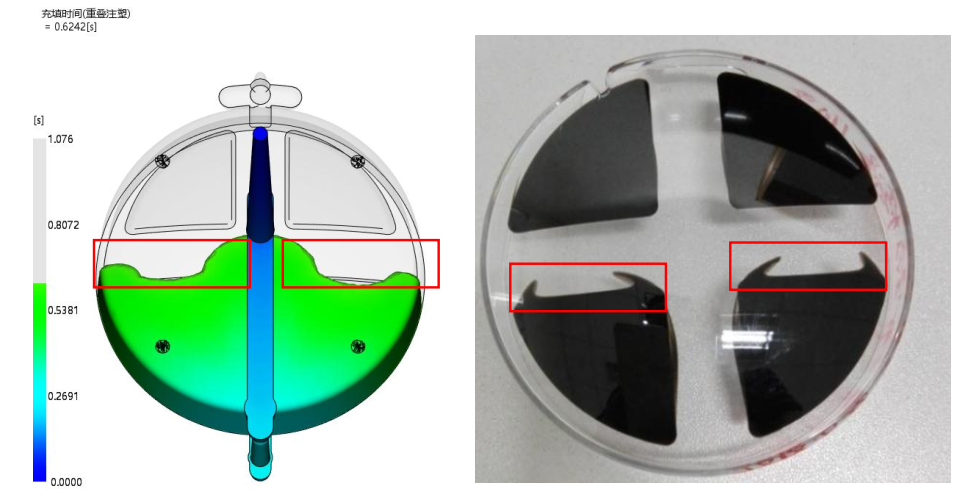

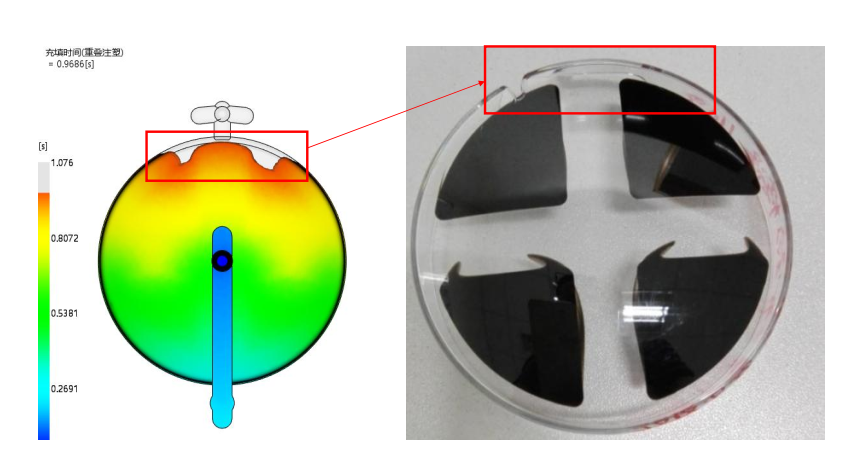

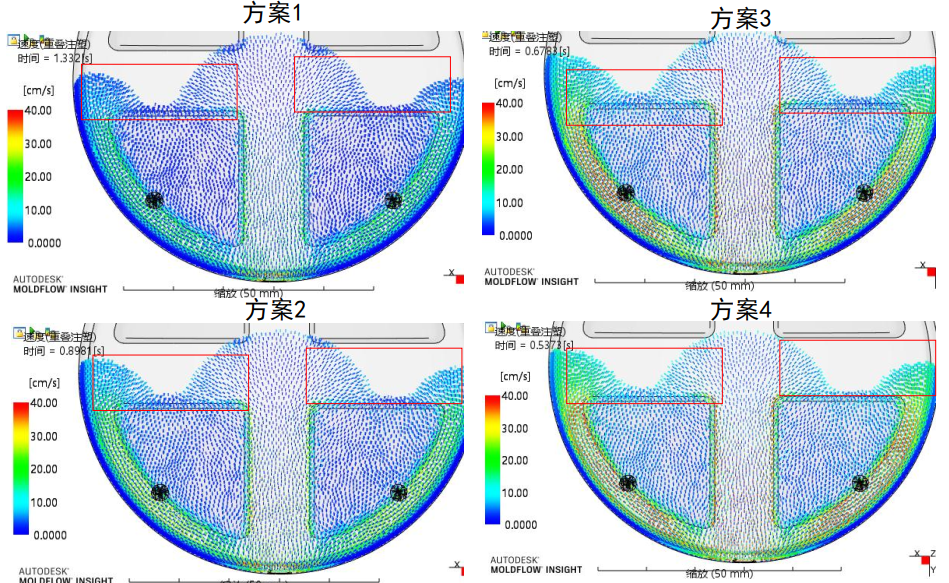

The mold flow analysis found that the flow trend is consistent with the actual filling flow, which can be compared with the results shown in the following figure:

|

|

It is mentioned in the theoretical research that there is scouring and friction between the second shot and the first shot in two-color molding. After the first shot molding is completed, the second shot plastic will produce secondary melting and molecular structure displacement and destruction on the cooled plastic surface under the scouring of high temperature, high pressure and high speed . From the filling results in the figure below, it can be seen that the second shot rubber material fills through the first shot surface, especially in the edge area of the first shot at a faster speed than in the middle area. Therefore, the scouring force of the second shot rubber material on the edge has a greater impact than in the middle area. Therefore, when the second shot rubber material is filled, the rubber material in the edge area of the first shot will melt and fill with the flow front of the second shot.

OSIAS Ford F150 Hard Tonneau Cover

OSIAS Power Steering Pump For 2007 Honda Accord

OSIAS Tri-Fold Hard Truck Bed Tonneau Cover For Chevy Colorado

Milwaukee 2767-20 M18 FUEL High Torque Impact Wrench with Friction Ring

OSIAS Parts

OSIAS 2.8L Fuel Surge Tank

OSIAS Truck Bed Tonneau Cover For Ford Maverick

OSIAS 6.7 Cummins Egr Delete Kit

OSIAS Tri-Fold Hard Truck Bed Tonneau Cover For Chevy Colorado

OSIAS Jeep Gladiator Tonneau Cover

OSIAS Chevrolet Silverado Tonneau Cover 2014-2018

Secondary Air Injection Pump