Should I Purchase injection mold in USA or China?

If your company needs injection molding services to manufacture plastic parts, one of the first and most crucial decisions to make is whether you want to choose an injection molding factory in your home country or overseas. Although many countries provide mold manufacturing services, China is the main participant in this market. Because the cost of injection molding in China is much cheaper than in the United States or Europe. By using injection molds made in China, you may save 20% -60% of costs and have faster delivery times.

The advantages of injection molding in China

1. Price

Many injection molding companies in China produce molds and molded parts with similar quality compared to companies in the United States and Europe, but at much lower prices. The choice is always very clear, whether it is the production of plastic parts or the development of molds themselves, the prices in China are much lower than those in other countries. To save you more profits and costs.

2. Quality

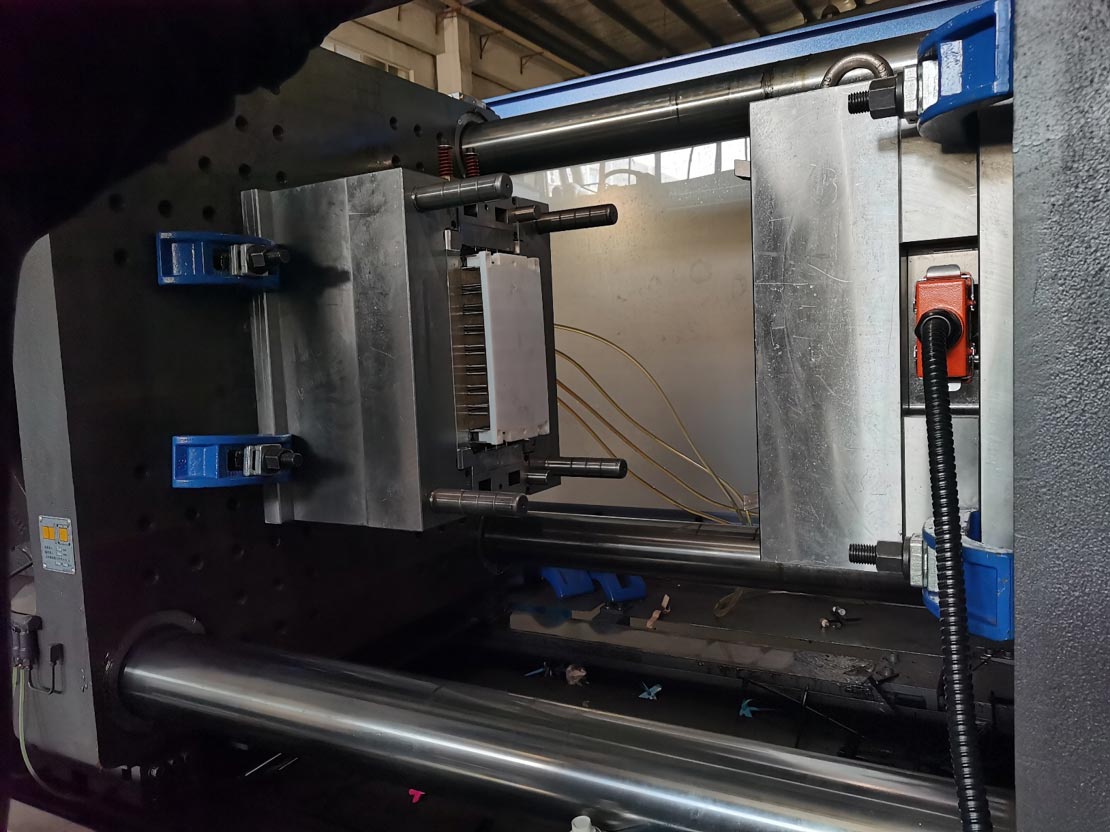

There are so many injection mold manufacturers and injection molding factories in China for a reason. In fact, for decades, manufacturing has been a core component of China. There are many injection mold manufacturers in China that provide services to companies and customers worldwide.

3. Delivery time

The delivery time for injection molding in China is relatively short. Usually, this takes 3-8 weeks, depending on the size and complexity of the tool.

After understanding the advantages of cooperating with Chinese injection molding companies, we also need to consider the following precautions when cooperating with Chinese injection molding companies:

1. You need to have clear and effective communication between your company and Chinese mold manufacturers. Collaborating with mold manufacturing services located in different countries, using different languages and cultures can increase the complexity of communication. Therefore, when choosing an injection molding company, it is best to choose a mold company that has professional connections with foreign customers and rich export experience .

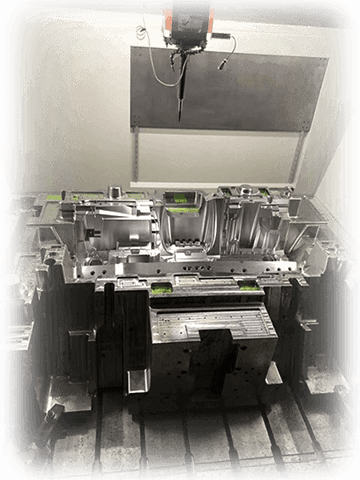

If the mold is very complex, you need to confirm whether the mold manufacturer can handle the complex mold you need. The complexity of plastic parts directly affects the complexity of molds. So when choosing a partner, it is important to confirm whether they have extensive injection molding experience and can solve various possible problems.

If you want to save communication costs and time, you can consider a one-stop injection molding service. One stop injection molding services include mold design and manufacturing, product injection molding processing, plastic shell surface treatment (spraying, screen printing, etc.), and other one-stop outsourcing services. Why do so many plastic injection molding factories emphasize one-stop injection molding services? Because it can not only reduce the cost of injection molding, but also save a lot of time. One stop injection molding service greatly improves production efficiency. The one-stop service factory is also very professional and has sufficient strength to provide you with better service.

Ding Zhou Mould focuses on the field of injection molding, providing strict program management from design to production, and providing high-quality injection molded parts to our customers. We know that you are currently making some key decisions that will affect the quality and efficiency of your future plastic parts. If you have any injection molding issues, please contact us promptly.

Share to: