The role of mold temperature setting in injection molding production

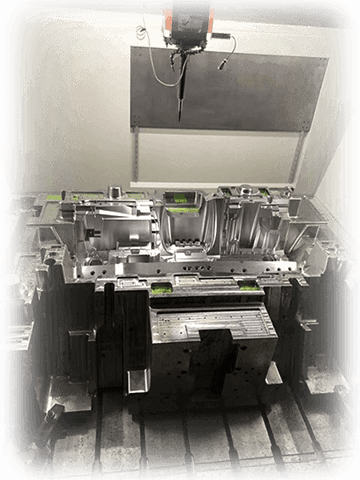

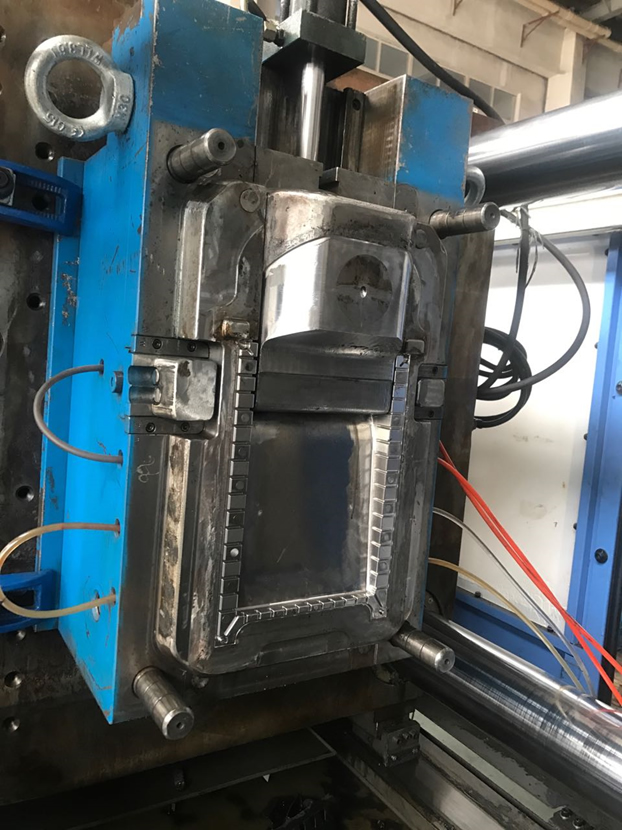

When molding engineering plastics, such as POM、PA、PC and ABS, it is very important to ensure the correct surface temperature of various molds. for example, the plastic shell of electronic products, especially after the mold design meets the basic product requirements, the injection molding machine operator must also be assisted by the mold temperature control equipment to produce various plastic products with good quality. only after the close and perfect cooperation between mold design and manufacturing and mold trial stage, the operator can avoid many problems in the subsequent mold production stage .

For the plastic shell of mobile power supply and the shell of intelligent electronic products, the mold surface temperature is too low, which usually produces poor appearance of various plastic products, and the defects are easy to identify. It is found that the surface temperature of the die is too low, which will also lead to the reduction of part size when the product is used at high temperature. Too low mold surface temperature is easy to reduce the shrinkage of various plastic parts, but the shrinkage of molded products becomes larger.

The shrinkage of ordinary engineering plastic molds and products after molding are closely related to the surface temperature of molds and the wall thickness of products. The uneven heat distribution in the mold will lead to different shrinkage of plastic products, resulting in the size of many plastic products exceeding the standard. If it is found that the size of plastic products needs to be stabilized through a long cooling time, if the surface temperature control of the mold is not good. This is due to the continuous rise of the temperature of the die and the long time to reach equilibrium. The molding cycle is prolonged due to the uneven heat distribution in different areas on the mold surface, which leads to the continuous reduction of the production efficiency of injection molding products and the increase of molding cost.

Share to:

Share to: