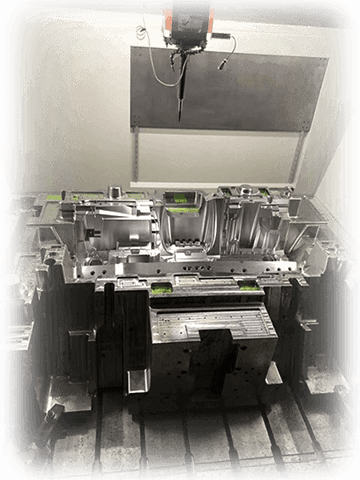

Design and development of injection mold for plastic shell of precision instrument

1.Bemould is a professional enterprise specializing in the design, manufacturing and

processing of precision injection molds, equipped with professional design and

development personnel and injection mold manufacturers. It has professional

supporting equipment for injection mold manufacturing, with exquisite

technology and excellent equipment;

2.From receiving drawing→ establishing 2D / 3D model → drawing

confirmation → CAD injection mold manufacturing → machining / CNC processing /

EDM processing → mold assembly → mold test → sample confirmation → mold

delivery / batch production → delivery, a complete set of process services

ensure the quality of the mold and provide you with a more solid guarantee.

3.Processing equipment: CNC milling, precision carving, EDM, wire cutting,

drilling machine, grinder, ordinary milling machine, CNC machining center .

4.Processing capacity: injection mold design, mold manufacturing and

injection molding processing.

5.Mold material: P20 / 718 / 718H / 2738 / 2316 / S136 / for your choice,

mold base: 45# pre hardening > 30hrc.

6.Cooling system: optimize the design of circulating water, improve

production efficiency and reduce your cost.

7.Medium term treatment: quenching and tempering to improve hardness.

8. Post treatment: nitriding (nitrogen treatment) has low temperature and small

deformation. It has high surface hardness (greater than HV850) and wear resistance without quenching.

9.Service life: P20 is frequently used for no less than 300000 mold times .

Share to: