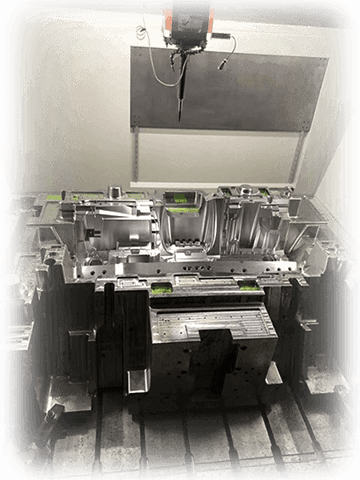

Injection molds maintenance specification in Bemould

The Aim

In order to ensure the normal production of molds and reduce issues and quality problems, the rational use, maintenance, maintenance and management of molds are very important to prolong the service life of molds, reduce costs, improve the quality of parts and improve the technical status of molds, which is an important work to ensure the normal production of injection molding.

The mold shall be maintained before, during and after production. Maintenance items and precautions:

Mold maintenance before production::

Scrub the dust, oil stain and rust on the mold surface and remove the dirt on the surface before putting the mold into the injection molding machine.

Use air gun or rag, detergent or alcohol (alcohol for mirror mold) to clean the oil stain on the mold surface.

Check whether there are foreign matters in the cooling water channel of the mold to ensure that the water channel is smooth.

Check whether the circular arc in the sprue sleeve of the mold is damaged and whether there is residual foreign matter. If there is any, it must be cleaned.

Moving parts: such as thimble, spring, hydraulic cylinder, slider, whether there is rust, bending and fracture, and whether the movement must be smooth.

Maintenance of mould in production :

Check and maintain the molds produced on the machine every day.

Check whether the guide post, guide sleeve and slide block of the mold are damaged or have foreign matters on them, and conduct refueling maintenance once a day.

Clean the foreign matters and oil stains on the parting surface and exhaust groove of the mold, and wipe them with air gun or rag, detergent or alcohol once a day.

Maintenance of mould after production :

Check whether each part of the mold is damaged.

Clean the oil stain on the parting surface and the remaining sundries in the mold cavity, and spray anti rust oil.

Blow dry the remaining water on the cooling water channel.

Matters needing attention:

When maintaining the mold, you must wear labor protection articles. Heavy objects must be operated with a crane. It is strictly prohibited to lift the mold directly by hand to prevent injury to limbs.

Rust prevention of the mold is necessary. After the maintenance of the mold, special attention should be paid to the rust prevention action of the mold. The remaining water in the water channel must be blown dry with an air gun.

Too much lubricating oil can not bring better lubrication effect, just an appropriate amount.

After the maintenance and installation of the mold, pay attention to the number and direction of the inserts and other parts. Do not install them reversely. Check whether the screws are completely used up. When installing the screws, lock them diagonally 。